Automated characterization of recycled aggregates using deep learning

Domains

Environenment

Habitat

Technologies

Sensors

Construction systems with high environmental quality for the new building

Challenges

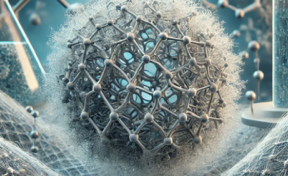

The construction sector is the largest consumer of natural materials of mineral origin in Europe, but also the largest producer of waste. In order to encourage the circular economy, the European Horizon 2020 program, the objective of which was to recover at least 70% of inert construction waste by 2020, is followed by the law relating to energy transition for green growth. which imposes the increase in the use of materials from the recycling of construction waste from 2020.

The great variability of supplies requires the industrialist to know precisely the composition of the recycled aggregates. Today this characterization is carried out by manual sorting. This process is long, expensive, with results that are not very reproducible.

Consequently, these limits in the characterization of recycled aggregates constrain their use and do not allow them to be valued in uses with higher added value such as recycled concrete.

Innovative solution

Artificial Intelligence at the service of the recycling of inert construction waste through the rapid and automated characterization of recycled aggregates to better control their quality and better recover them.

APPLICATIONS

Automatic characterization of construction waste for recovery.

AVANTAGES

-

Fast and automated analysis, compared to manual methods used today. Allows real-time control..

-

Characterizes the nature as well as the shape of the grains (can replace a particle size test).

-

Fineness of the analysis: much finer composition than that proposed by the EN 933-11 standard (at least 17 classes vs 6 for the standard)..

DEVELOPMENT : TRL 5/6

-

Functional recycled aggregate image acquisition device.

-

Trained individual recycled aggregate image localization and extraction AI.

-

IA de localisation et d'extraction d'images de granulats recyclés individuels entraînée.

-

Need to increase the database of labeled images to improve detection in real conditions.

-

Development of a semi-supervised learning method in order to limit data requirements (in particular mass data)

How it works

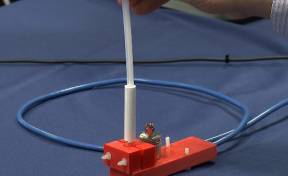

ARCADE technology consists of an acquisition device associated with an AI for data analysis.

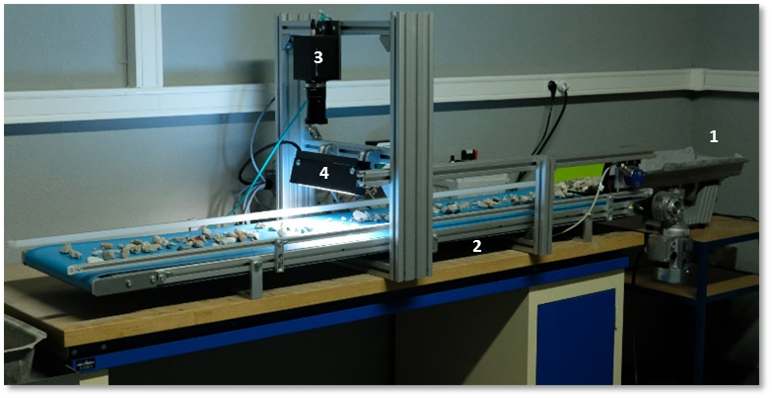

The acquisition device: a vibrating distributor (1) receives the aggregates to be analyzed and feeds a conveyor belt (2) while controlling the density of the grains distributed. The conveyor belt passes the aggregates in front of a high definition linear camera sensitive to the visible and near infrared spectra (3), in order to improve the detection of visually similar classes of aggregates. The intensity as well as the orientation of the lighting (4) of the carpet in the acquisition field is controlled so as to have the maximum of light entering the objective of the camera.

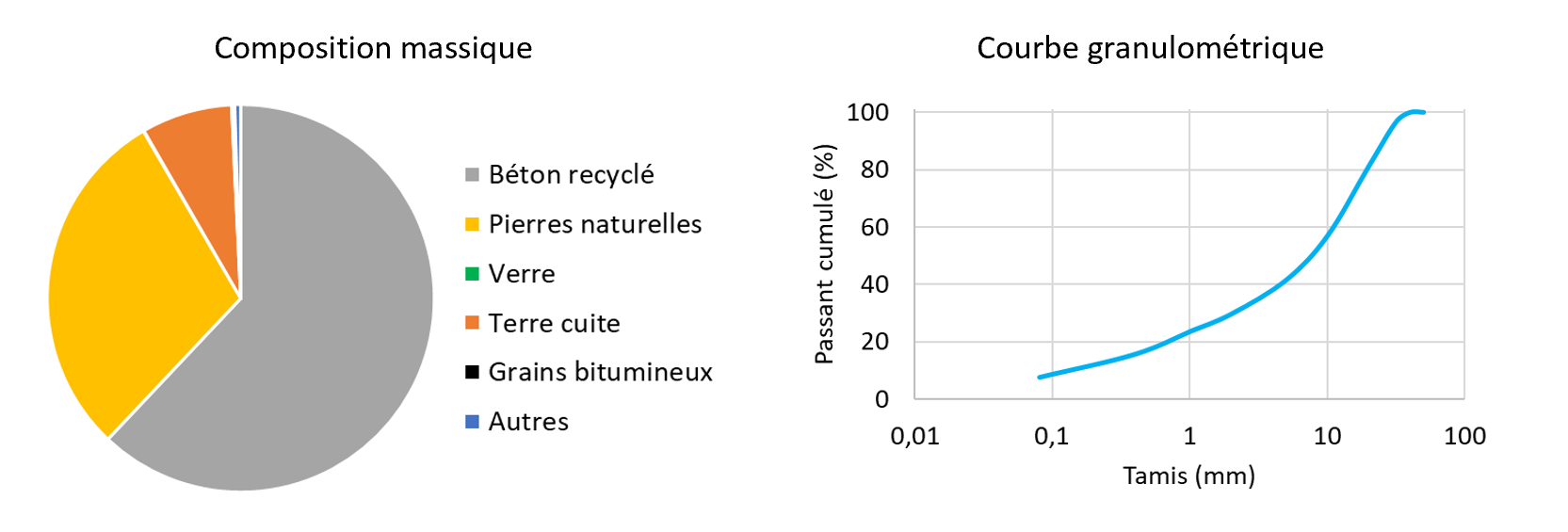

Data analysis: The software part constitutes the innovative part of the proposed device. A convolutional neural network makes it possible to individually and automatically extract each grain and then determine its nature and mass. Accuracy in terms of classification is around 97% while errors in mass estimates are around 3%.

The entire acquisition and analysis device is controlled by a computer with a graphics card specifically dedicated to deep learning. During the same process there is also the possibility to determine other properties of the recycled aggregates such as the granulometric curve to obtain a technical data sheet.

After passing through the device, the aggregates are recovered or can be reinjected into the stock as needed.

Inventors

Developed by a research team from the LaSIE laboratory (CNRS, La Rochelle University)

IP

1 patent: FR2106444

PARTNERSHIP

Assignment of patent exploitation rights to a company that will market the technology to construction/environment/recycling players

Contact

Valérie SCHOEN

%76%2e%73%63%68%6f%65%6e%40%61%73%74%2d%69%6e%6e%6f%76%61%74%69%6f%6e%73%2e%63%6f%6d

+33 (0)7 62 10 02 73

Benoît SORE

%62%2e%73%6f%72%65%40%61%73%74%2d%69%6e%6e%6f%76%61%74%69%6f%6e%73%2e%63%6f%6d

+33 (0)6 63 51 28 76