Mycosporines Innovative uv anti-aging cosmetic ingredient inspired by marine biomimicry

Domains

Health and wellbeing

Environenment

Technology Green chemistry processes

Challenges

The environmental impacts of sunscreen usage are quite concerning. It's been estimated that more than 25,000 tons of sunscreen products find their way into our seas and oceans annually. This influx wreaks havoc on microalgae, phytoplankton, corals, and ultimately leads to the demise of various fish species.

The market trend towards "organic," "non-toxic," and "natural" sunscreens is gaining momentum. However, the outcomes often don't live up to the marketing claims, especially when it comes to efficacy. Relying solely on mineral filters doesn't necessarily ensure SPF 50 protection.

There are currently 27 approved sunscreen filters, with only two being "mineral" in nature, relying on titanium dioxide and zinc oxide. Nonetheless, there's concern that these substances may release particles into the ocean, and the full extent of their impact on marine life remains unclear.

Innovative solution

Development of in-vitro Mycosporine glucoside with UV and antioxidant properties for use in cosmetics such as sunscreens.

APPLICATIONS

-

Primarily cosmetics: sunscreens, any cosmetic product containing sunscreen filters.

COMPETITIVES ADVANTAGES

-

Production without the addition of organic solvents, under mild conditions of temperature, pH, and pressure

-

Environmentally friendly UV protection

-

Effective UV protection

-

Stability of mycosporines in the formulation

DEVELOPMENT STATUS : TRL 2

What remains to be done:

- Sourcing of raw materials

- Preclinical tests

- Clinical tests

How it works

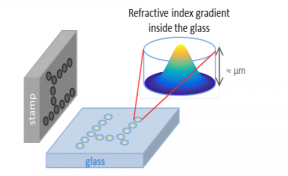

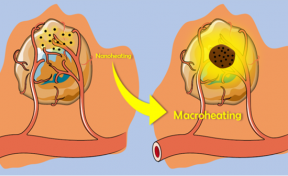

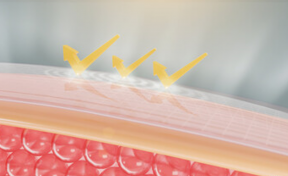

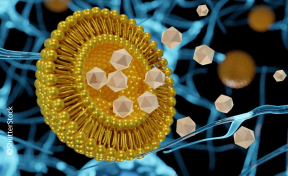

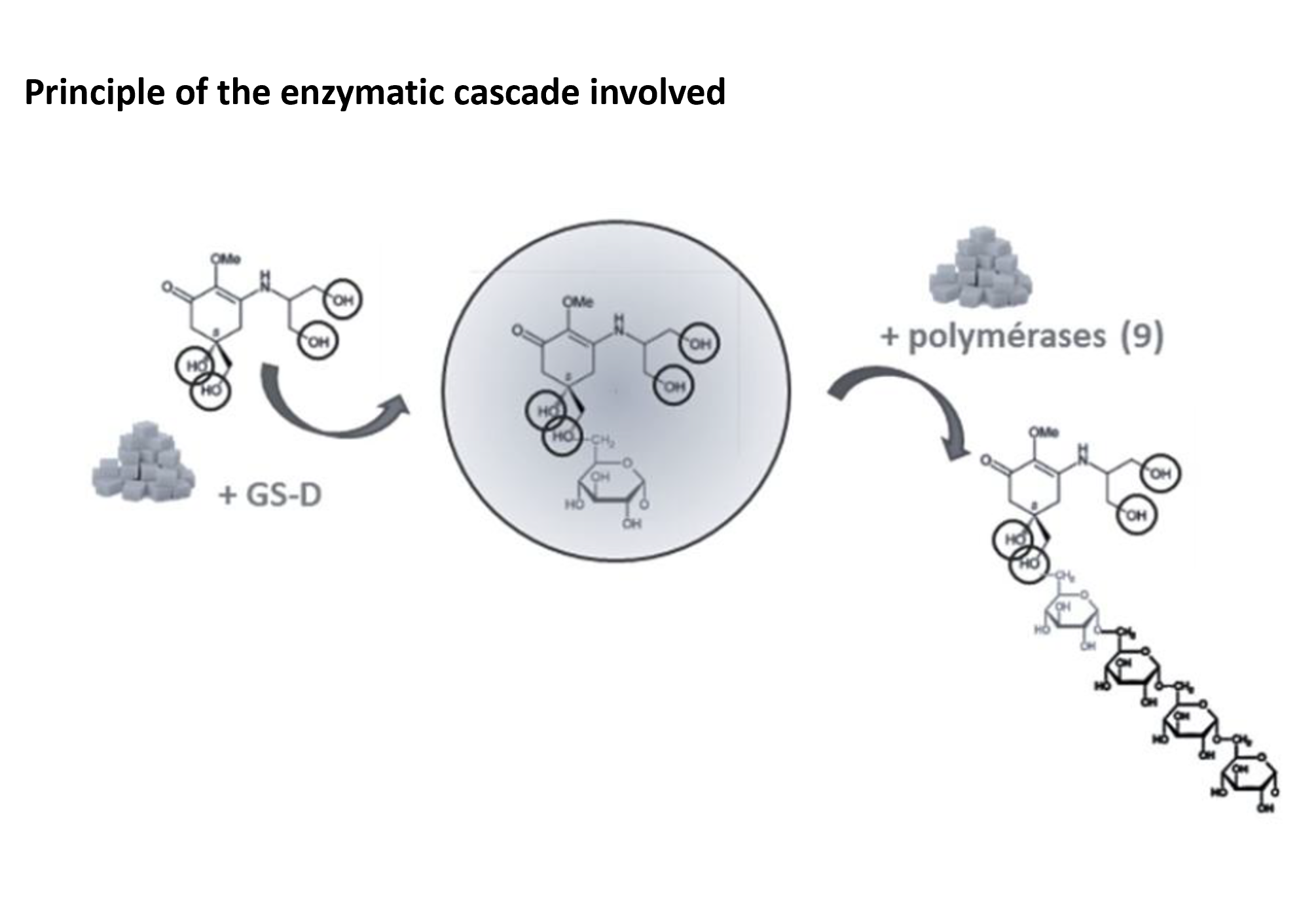

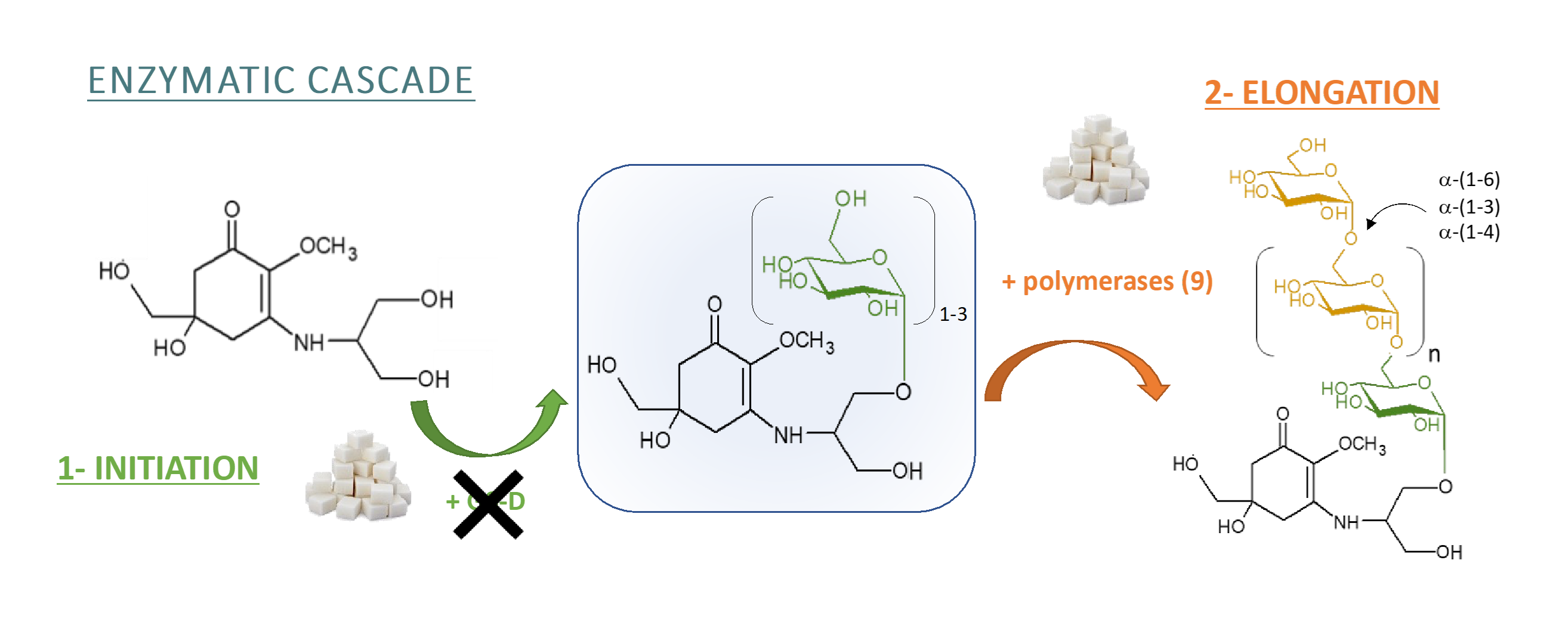

The patent is centred around producing glucosylated versions of mycosporines through an enzymatic cascade process involving

α-transglucosylases. These enzymes use sucrose from beet or sugarcane to synthetise or embellish polymers consisting of high molecular weight glucosyl units. The enzymatic cascade method employed in this process has the advantage of sidestepping chemical reactions, thereby avoiding several steps and the need for metal catalysts or potent acids. The enzymatic process comprises the following:

The initial step involves glucosylation to yield intermediate products: glucosylated mycosporines.

A subsequent step entails elongating and polymerising intermediate products using other α-transglucosylases: polymerised glucosylated mycosporines. It is this latter stage that enables the synthesis of final products, depending on their degree of polymerisation.

The production of glucosylated mycosporines takes place entirely in an aqueous medium without the addition of any organic solvents. The end products are mycosporine derivatives featuring elongated glucosyl chains, which can be readily utilised in the prevention and protection of dermal cells.

Inventors

Developed by Susana MATOS FERNANDES – (IPREM : UPPA, CNRS) & Claire MOULIS (TBI / INSA Toulouse)

IP

Patent : FR2208098 - PCT/FR2023/051238

PARTERSHIPS

License and/or partnerships and co-development, particularly for sourcing and characterization

Contact

Carlos LARRAYA

%63%2e%6c%61%72%72%61%79%61%40%61%73%74%2d%69%6e%6e%6f%76%61%74%69%6f%6e%73%2e%63%6f%6d

+33 (0)6 18 40 63 51